Plastic Solutions for Modern Industry and Agriculture #

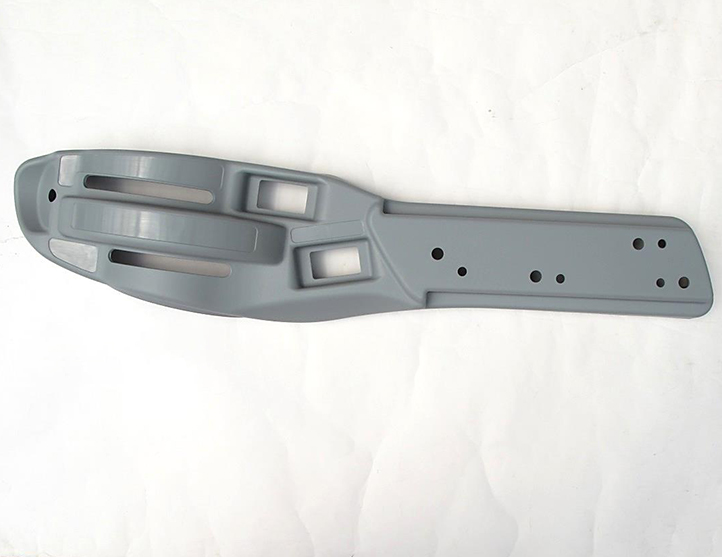

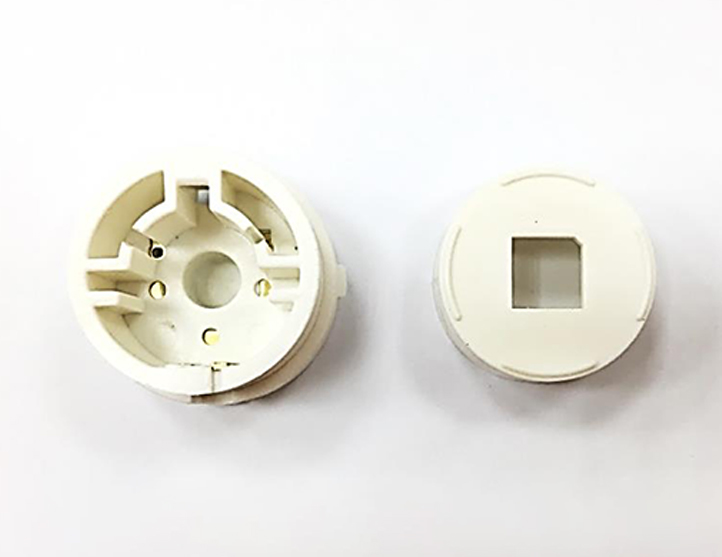

The transition from traditional metal components to high-performance plastic parts in industrial and agricultural machinery has brought significant benefits. By leveraging the unique properties of engineered plastics, manufacturers can achieve greater durability, wear resistance, and temperature stability, while also reducing the overall weight of equipment.

Advantages of Plastic Components #

- Durability and Wear Resistance: Plastic parts offer excellent resistance to wear and tear, ensuring a longer service life for machinery and tools.

- Temperature Stability: These materials perform reliably under both high and low temperature conditions.

- Lightweight Design: The reduced weight of plastic components leads to lower fuel consumption and easier handling.

- Easy Recycling: Plastics are easier to recycle compared to metals, supporting sustainability initiatives.

- Cost Efficiency: The manufacturing process allows for high plasticity and good fluidity, minimizing the need for secondary trimming and reducing production costs.

- Environmental Impact: Lower fuel consumption translates to reduced carbon dioxide emissions, contributing to environmental protection.

Materials Utilized #

A variety of advanced plastic materials are employed to meet the diverse needs of industrial and agricultural applications, including:

- ABS

- ASA

- AES

- PES

- PPS

- PC

- PMMA

- PP

These materials are selected for their specific properties, ensuring optimal performance and competitiveness in the market.

OEM/ODM Service Capabilities #

Our comprehensive OEM/ODM services cover every stage of product development and manufacturing:

- R&D: Innovative research and development to meet unique client requirements.

- Manufacturing Capacity: Robust production capabilities for large and small batches.

- Quality and Inspection: Rigorous quality control and inspection processes.

- Customization: Tailored solutions to fit specific application needs.

For more information or to discuss your specific requirements, please contact us.